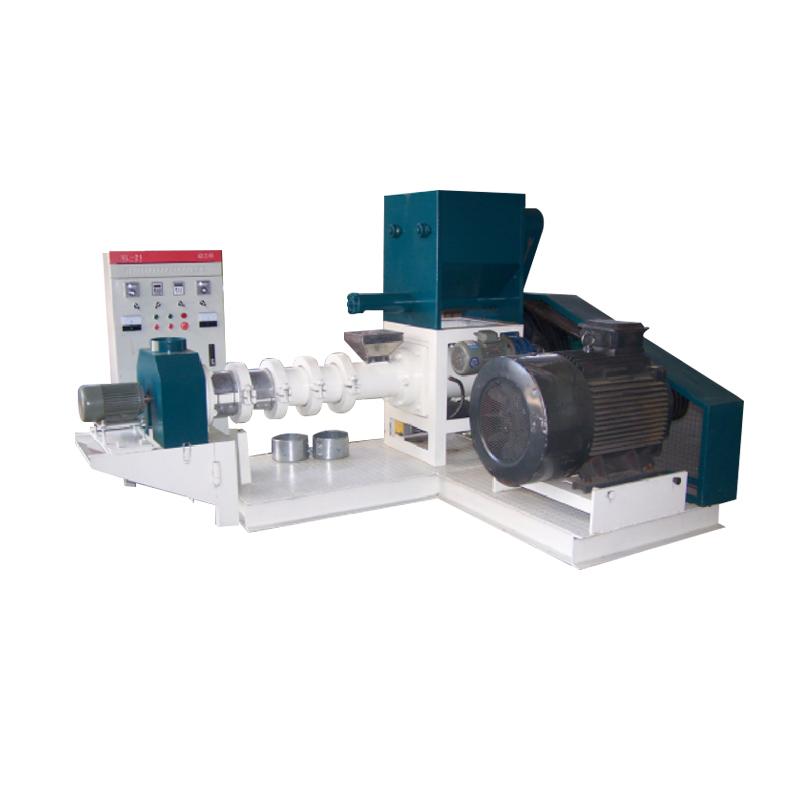

Dog Food Products Extruder 1.IntroductionDog Food Products Extruder ,The computerized massive workable canines ingredients manufacturing line makes powdered raw resources such as corn flour into canines foods through the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce dogs foods of a range of shapes and sizes.

Contact Now

Cat And Dog Food Extruder1.Introduction The Cat And Dog Food Extruder makes powdered uncooked property which consists of corn flour into pups elements with the useful resource of the approach of blending,extruding,drying,flavoring and cooling. Cat And Dog Food Extruder can produce pups substances of higher than a few sizes and styles.

Contact Now

Dog Food Production Line1.IntroductionThe automatic dog food production line makes powdered raw materials such as corn flour into dog food through the process of mixing,extruding,drying,flavoring and cooling. The same production line can produce dog food of various shapes and sizes.

Contact Now

Dog Food Production Machine1 IntroductionThe automatic canine food production line makes powdered uncooked substances along with corn flour into dog food through the method of blending,extruding,drying,flavoring and cooling. the identical manufacturing line can produce canine meals of various styles and sizes.

Contact Now

Dog Food Production Extruder1.IntroductionThe automated dog food production line makes powdered uncooked substances which includes corn flour into canine meals via the technique of blending,extruding,drying,flavoring and cooling. the equal manufacturing line can produce dog meals of various sizes and styles.

Contact Now

Big Capacity Dog Food Production Line1.IntroductionThe automatic big capacity dog food production line makes powdered raw materials such as corn flour into dog food through the process of mixing,extruding,drying,flavoring and cooling. The same production line can produce dog food of various shapes and sizes.

Contact Now

Pet Dog Food Extruder Machine1 IntroductionThe automated dog meals production line makes powdered raw materials such as corn flour into dog meals thru the manner of mixing,extruding,drying,flavoring and cooling. the equal manufacturing line can produce dog food of various shapes and sizes.

Contact Now

Dog Food Production Extruder Line1 IntroductionThis fully automatic dog food making machine uses grain or powder as the raw material ,includes mixing,extruding,drying,flavoring and cooling parts.

Contact Now

Dog Food Production Line1 IntroductionThe automatic canine food manufacturing line makes powdered raw materials consisting of corn flour into dog food through the manner of blending,extruding,drying,flavoring and cooling. the same production line can produce dog food of various styles and sizes.

Contact Now

Dog Food Extruder Machine1 IntroductionDog Food Extruder Machine makes use of grain pellets or powders as uncooked substances and consists of many processes. Puffing is an important link in the process of dog food processing, and the expansion process is also a process of dog food raw material molding. During the molding process, water is added in the form of steam to make the raw material starch in dog food gelatinize, and the temperature rises to 100 ℃~180 ℃.

Contact Now

Pet Food Dog Production Line1 IntroductionPet Food Dog Production Line Composed of multiple processes.The puffing process is also a process of raw material forming of dog food, so dog food through the puffing process generally has high nutritional value that is easy to digest and absorb. Pet Food Dog Production Line operation is simple and easy to learn, so as to ensure that the product is completed in a specific temperature, pressure, humidity and time.

Contact Now

Big Pet Dog Food Extruder1.IntroductionBig Pet Dog Food Extruder ,The computerized huge potential canine meals manufacturing line makes powdered uncooked substances such as corn flour into canine meals thru the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce canine meals of a number of shapes and sizes.

Contact Now

Industrial Dog Food Production Line1 IntroductionDog food is specially provided for pets, tiny animals feed, between human food and ancient eutherian mammal and poultry feed animal food, principally for all types of pets to produce basic insurance, growth and health needed nutrients. it's the benefits of comprehensive nutrition, high digestion and absorption rate, scientific formula, quality normal, convenient feeding and use, and might stop some diseases.

Contact Now

Cat Pet Food Production Line Extruder1 IntroductionCat Pet Food Production Line Extruder can divide into electrical form and steam type which in accordance to the extruder heating method. Cat Pet Food Production Line Extruder functionality can up to 100-5000kg/h. Cat Pet Food Production Line Extruder manufacturing line can produce all sorts of merchandise with one-of-a-kind shapes via altering the mildew as bone, heart, circular, triangle and others shapes.

Contact Now

Pet Food Double Screw Extruder Machine 1.IntroductionDog Cat Food Extruder Machine ,The computerized large possible canines foods manufacturing line makes powdered raw supplies such as corn flour into pups resources by using the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce pups factors of a range of shapes and sizes.

Contact Now

Dog Food Extruder1.IntroductionMainly used in the production and processing of various floating and sinking aquatic feeds, especially suitable for the production of various floating aquatic feeds, and also widely used in the production and processing of pet food. In the single screw extrusion cavity, the material is basically closely around the screw, a continuous ribbon in a spiral shape.

Contact Now

Dog Food Production Line Extruder Machine1 IntroductionThe automatic dog food production line makes powdered uncooked substances along with corn flour into dog food through the method of blending,extruding,drying,flavoring and cooling. the identical manufacturing line can produce pet meals of various styles and sizes.

Contact Now

Big Capacity Dog Food Extruder 1.IntroductionMainly used in the production and processing of various floating and sinkingfeeds, specially appropriate for the manufacturing of various floating aquatic feeds, and additionally extensively used in the production and processing of pet food.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.36*1.

Contact Now

Cat Dog Pet Food Extruder Machinery 1.IntroductionWith the improvement of society, the demand for all sorts of pet meals for dogs, cats and birds has expanded dramatically and is shifting in the direction of standardization and scale. According to the market demand, Bright has developed a new Cat Dog Pet Food Extruder Machinery.

Contact Now

Dog Pet Cat Food Twin Screw Extruder Production Line 1.IntroductionThe automated pet cat dog food manufacturing line makes powdered raw substances inclusive of corn flour into canine meals via the manner of mixing, extruding drying, flavoring and cooling. the identical production line can produce canine meals of numerous sizes and styles.

Contact Now

Dog Food Making Machine Production Line1 IntroductionPet Feed Dog Food Extruder Machine Production Line can divide into electrical kind and steam kind which in accordance to the extruder heating method. Pet Feed Dog Food Extruder Machine Production Line capability can up to 100-5000kg/h. Pet Feed Dog Food Extruder Machine Production Line can produce all types of merchandise with one-of-a-kind shapes through altering the mildew as bone, heart, circular, triangle and others shapes.

Contact Now

Dog Chews Treats Production Line1.Introduction Dog Chews Treats Production Line might also moreover in addition want to produce all kinds of canines chews, as an instance, single shade and double-shade canines treat, twist treats and so on.Dog chews snacks are a type of snacks in special designed and developed for pet home puppies to meet the chewing and biting needs of puppies as they increase up. at the equal time, canines chews can maintain oral fitness and save you the formation of dental plaque and calculus.

Contact Now

Dog Cat Food Extruder1.Introduction The Dog Cat Food Extruder makes powdered raw property which consists of corn flour into pups factors by way of the approach of blending,extruding,drying,flavoring and cooling. the Automatic Pet Food Kibbles Production can produce home puppies elements of a fluctuate of sizes and styles.

Contact Now

Dog Food Extruder1.IntroductionMainly used in the production and processing of various floating and sinking aquatic feeds, especially suitable for the production of various floating aquatic feeds, and also widely used in the production and processing of pet food.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.36*1.67*0.85mBRT80250-300kg/h22kw

Contact Now