Fried Chips Machine1.IntroductionThe automatic fried snack manufacturing line makes powdered uncooked substances which incorporates corn flour into fried snack via the technique of mixing,extruding,frying,flavoring and cooling. the identical production line can produce fried snacks of severa styles and sizes.

Contact Now

Fried Snacks Bugle Production Line1.IntroductionThis production line could produce bugle shape fried snacks. The main raw materials for the production of bugles snack are corn starch, rice starch and potato starch.

Contact Now

Fried Snacks Processing Line1.IntroductionIn recent years, fried snacks have become very popular, and various shapes and flavors are very popular among consumers.

Contact Now

Fried Kurkure Snacks Food Makes Machine1.IntroductionFrying type: ①Flour mixing machine→②Screw conveyor→③Rotary head extruder→④Elevator→⑤Separation cylinder→⑥Vibrating feeder→⑦Continuous fryer→⑧Vibration deoiling machine→⑨Seasoning lineCheetos is a special type of squeezed food that is very crunchy in the mouth. The corn grits are mixed with a certain proportion of water and then enter the rotary head extruder.

Contact Now

Fried Snack Making Line1.IntroductionThe automatic fried snack production line makes powdered raw materials which incorporates corn flour into fried snack thru the approach of blending,extruding,frying,flavoring and cooling. the equal production line can produce fried snacks of severa shapes and sizes.

Contact Now

Fried Snack Food Machine1.IntroductionThe automated fried snack production line makes powdered raw substances which includes corn flour into fried snack through the method of mixing,extruding,frying,flavoring and cooling. the same production line can produce fried snacks of severa styles and sizes.

Contact Now

Fried Snack Production Line for Sale1.IntroductionThis production line should produce many shapes fried snacks.

Contact Now

Fried Snack Making Machine1.IntroductionThe automatic fried snack manufacturing line makes powdered raw substances which includes corn flour into fried snack through the method of mixing,extruding,frying,flavoring and cooling. the equal production line can produce fried snacks of numerous shapes and sizes.

Contact Now

Fried Snack Production Line1.IntroductionThis production line should produce many shapes fried snacks.

Contact Now

Fried Corn Bugle Chips Extruder Machines1 IntroductionThis manufacturing line could produce bugle shape fried snacks.

Contact Now

3d Pellet Food Machine1.Introduction3d Pellet Food Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as uncooked materials, which can be barring lengthen extruded and prevent via ability of the use of twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 3d Pellet Food Machine can in addition be supporting the manufacturing of gorgeous crisp Angle, local crisp, duck egg circle and special 3D billets.

Contact Now

2D3D Pellet Snack Making Machine1.IntroductionThe automatic 2D3D snack production line makes powdered raw materials such as corn flour into 2D3D snack through the process of mixing,extruding,drying and cooling. The same production line can produce 2D3D snacks of various shapes and sizes.

Contact Now

2D3D Pellet Snack Machine 1.IntroductionThe automatic 2D3D snack production line makes powdered raw materials such as corn flour into 2D3D snack through the process of mixing,extruding,drying and cooling. The same production line can produce 2D3D snacks of various shapes and sizes.

Contact Now

Commercial Corn Chips Machine1.IntroductionCommercial Corn Chips Machine need to produce many shapes fried snacks.

Contact Now

2D3D Pellet Snack Extruder1.IntroductionThe automatic 2d3d snack production line makes powdered uncooked materials together with corn flour into 2d3d snack thru the machine of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of severa patterns and sizes.

Contact Now

Puff Snacks Food Machine Extruder1 IntroductionThe automatic puff snack manufacturing line makes powdered raw substances which include corn flour into puff snack thru the machine of blending,puffing,drying,flavoring and cooling. the same manufacturing line can produce puff snacks of diverse styles and sizes.

Contact Now

Automatic Pet Feed Pellet Machine1.Introduction The Automatic Pet Feed Pellet Machine makes powdered uncooked property which consists of corn flour into puppies substances with the useful resource of the method of blending,extruding,drying,flavoring and cooling. Automatic Pet Feed Pellet Machine can produce doggies substances of increased than a few sizes and styles.

Contact Now

2D3D Snack Pellet Making Machine1.IntroductionThe automated 2d3d snack manufacturing line makes powdered raw materials including corn flour into 2d3d snack via the technique of mixing,extruding,drying and cooling. the identical production line can produce 2d3d snacks of numerous sizes and patterns.

Contact Now

2D3D Pellet Snack Extruder Machine1.IntroductionThe automated 2d3d snack manufacturing line makes powdered uncooked materials which includes corn flour into 2d3d snack through the technique of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of diverse shapes and sizes.

Contact Now

Corn Puffs Snacks Making Machinery1 IntroductionThe automatic puff snack manufacturing line makes powdered raw substances which include corn flour into puff snack thru the machine of blending,puffing,drying,flavoring and cooling. The equal puff snack may be matched with first-rate system production traces in keeping with particular capability.

Contact Now

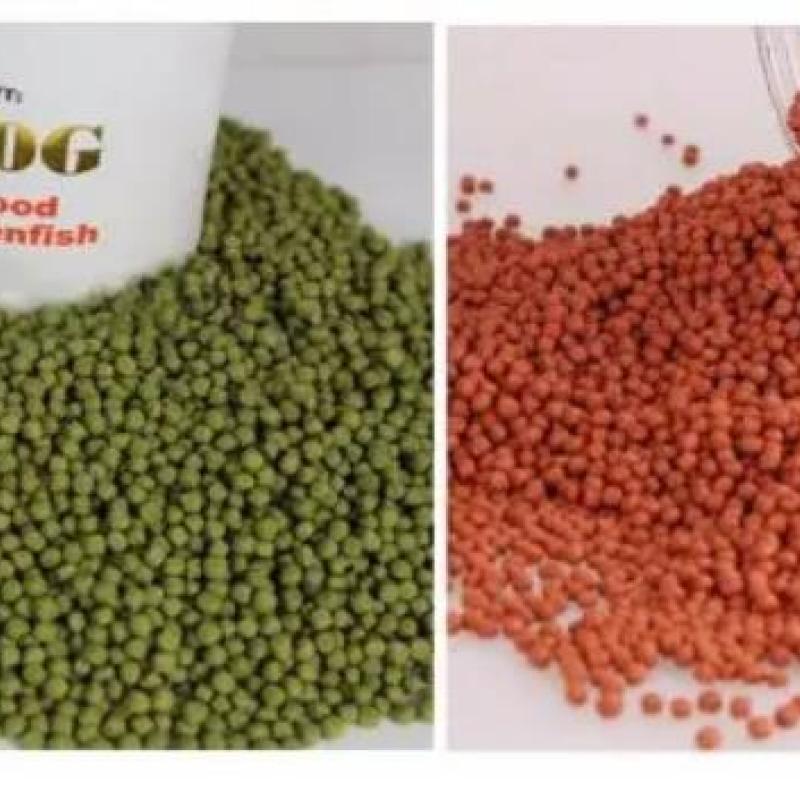

Dog Food Pellet Making Line Machine1 IntroductionDog Food Pellet Making Line Machine line makes use of grain pellets or powders as uncooked substances and consists of many processes. Mixing, extruding, drying, flavoring and cooling etc.

Contact Now

Commercial Corn Tortilla Making Machine1.IntroductionCommercial Corn Tortilla Making Machine want to produce many shapes fried snacks.

Contact Now

Cat Food Pellet Making Machine1.Introduction The Cat Food Pellet Making Machine makes powdered uncooked property which consists of corn flour into pups elements with the aid of way of the method of blending,extruding,drying,flavoring and cooling. the Automatic Pet Food Kibbles Production can produce domestic doggies factors of a fluctuate of sizes and styles.

Contact Now

2D3D Pellet Snack Production Line1.IntroductionThe automatic 2d3d snack production line makes powdered raw substances including corn flour into 2d3d snack through the system of mixing,extruding,drying and cooling. the identical production line can produce 2d3d snacks of numerous styles and sizes.

Contact Now